1. The working principle is different.

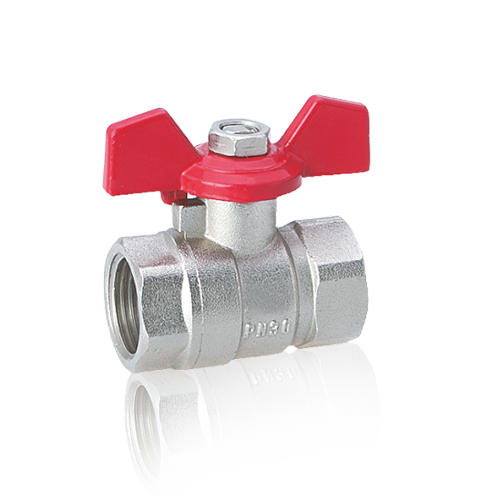

Copper ball valve: The ball valve is mainly used to cut off or connect the medium in the pipeline. It can also be used for fluid adjustment and control. Among them, the hard-sealed V-shaped ball valve has a V-shaped ball core and a hard alloy metal valve seat. Very strong shearing force, especially suitable for media containing fibers, small solid particles and other media.

Stainless steel ball valve: The working principle of the ball valve is to make the valve unblocked or blocked by rotating the valve core. The ball valve switch is light, small in size, can be made into a large diameter, reliable in sealing, simple in structure, easy to maintain, the sealing surface and the spherical surface are often closed, and it is not easy to be eroded by the medium, and it is widely used in various industries.

2. Different materials.

Copper ball valve: The material used is mainly composed of copper.

Stainless steel ball valve: The material used is mainly composed of stainless steel.

3. The temperature of the working environment is different.

Copper ball valve: If the working environment medium temperature exceeds 80 degrees, a copper ball valve must be used.

Stainless steel ball valve: If the temperature of the working environment does not exceed 80 degrees, you can use a stainless steel ball valve.

4. The price is different

Copper ball valve: The cost material is more expensive.

Stainless steel ball valve: The cost material is cheaper than copper ball valve.

5. Different applicable substances

Stainless steel ball valves can be used to control the flow of various types of fluids such as air, water, steam, various corrosive media, mud, oil, liquid metal and radioactive media;

Copper ball valves are suitable for general working media such as water, solvents, acids and natural gas, and also suitable for media with harsh working conditions, such as oxygen, hydrogen peroxide, methane and ethylene.

英语

英语 中文简体

中文简体 德语

德语 西班牙语

西班牙语