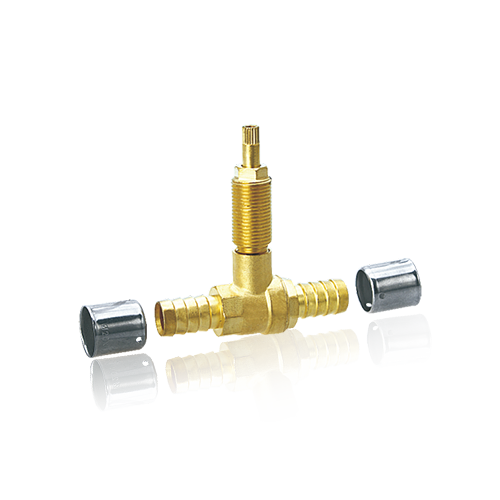

A Built-ln Ball Valve is a type of control valve with a rotary stem that connects the ball to the external lever. When the valve is opened, the ball is located in a cavity in the body, which is sealed by an o-ring. When closed, the ball is perpendicular to the flow. A shaft is connected to the valve through a pipe that connects the stem to an external control mechanism.

The valve stem and seat are the two primary components that form the ball valve. A spring-loaded plunger is used to close the valve. A flanged sleeve is also available. The spring-loaded plunger is used to close a built-in ball valve. A nut is used to secure the ball to the valve stem. The nut is used to tighten the valve, which is important when it is in a corrosive environment.

The Built-ln Ball Valve has a three-piece design that makes it easier to manufacture. The body of the valve is divided into three pieces along the cross-section, perpendicular to the axis of the channel. The valve stem and body are bi-sectionally symmetrical. This design creates a uniform look for the valve. Unlike other ball valves, which are usually made of two pieces, the built-ln Ball is easy to disassemble.

Another type of built-ln Ball Valve has a one-piece design and two-piece design. One piece has a single-piece body and a second piece includes a second end connection. These are easy to install and disassemble. Top-entry ball valves are suitable for low-pressure applications and media that is crystallizing or viscous. These valves have a small diameter, making them ideal for small-diameter flow.

These valves have a durable housing, and the ball and body are supported by seats. The upstream seat is adjacent to the inlet side, and the downstream seat is adjacent to the discharge side. In-line ball valves are available with a single-seat or double-seat design. A trunnion valve has a single-seat design. The lower-pressure version is a non-ball-valve.

The Built-ln Ball Valve is a patented design that has been adapted for industrial and domestic use. These valves are made of copper and zinc and are the most common material used for ball valves. Brass is extremely durable and able to withstand high temperatures and pressures. The copper and zinc in the alloy inhibit the growth of microbes. It also has a high corrosion resistance. Hence, it is a great choice for high-pressure applications.

The Built-ln Ball Valve has a single-seat design. This type is characterized by a rotary ball in its center bore. Generally, this type of valve has two end caps and a body. The end caps are clamped together, and the stem is connected to the valve. The valve body is also made of three pieces, which make it more versatile. When the rotor is assembled, it is connected to the pipe through threaded connections.

英语

英语 中文简体

中文简体 德语

德语 西班牙语

西班牙语